Injection molding is a manufacturing process that has revolutionized the production of plastic parts in various industries, including automotive, consumer goods, and electronics.

Shot Volume Injection Molding is a technique that focuses on the precise control of the plastic material's volume during the injection process. This method is particularly useful for producing parts with consistent and uniform wall thickness, which is crucial for maintaining structural integrity and performance.

The process involves the use of advanced control systems that monitor and adjust the volume of plastic being injected into the mold. This precision allows for better control over the cooling and solidification of the plastic, pilot fewer defects and a more consistent final product. Shot Volume Injection Molding is especially beneficial in the production of complex parts with multiple cavities, where uniformity is key to ensuring that each part functions as intended.

Statistical Process Control (SPC) Injection Molding is an approach that integrates statistical analysis into the injection molding process. The goal of SPC is to monitor and control the process variables in real-time, ensuring that the production is within specified limits and that any deviations are quickly identified and corrected. This proactive approach to quality control helps to small defects, reduce scrap rates, and maintain a high level of product consistency.

SPC Injection Molding involves the use of sensors and data acquisition systems that collect information on various process parameters, such as temperature, pressure, and flow rate. This data is then analyzed using statistical methods to identify trends and patterns that may indicate a need for process adjustments.

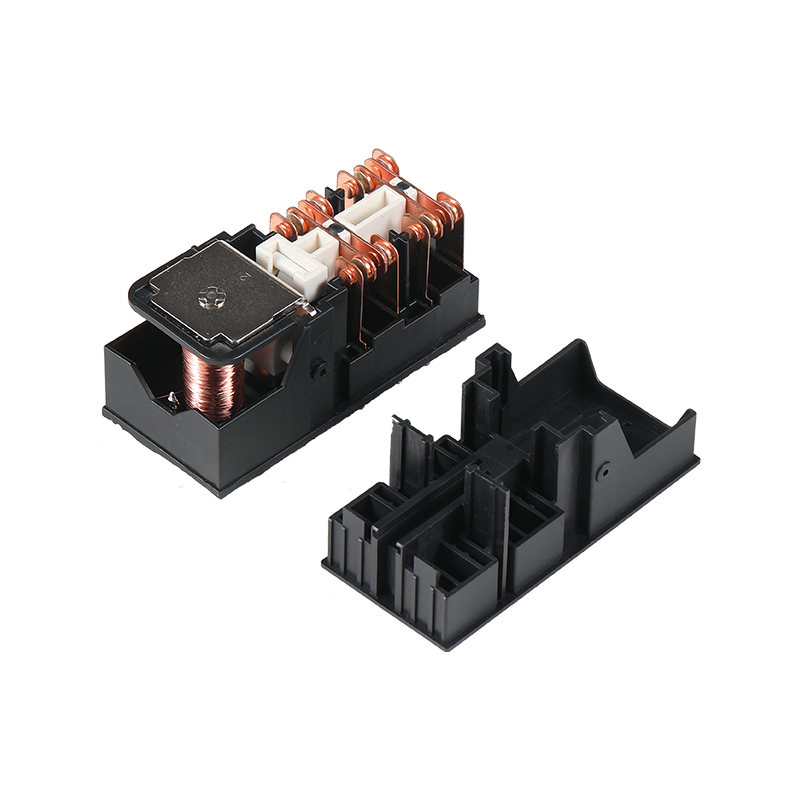

Precision Injection Molding is a technique that emphasizes the production of parts with tight tolerances and high dimensional accuracy. This method is particularly important in industries where the performance of the final product depends on the precision of its components, such as in the medical, aerospace, and electronics sectors. Precision Injection Molding requires the use of high-quality molds, advanced control systems, and carefully selected materials to achieve the desired level of accuracy.

The process involves meticulous design and engineering of the mold, ensuring that it can withstand the pressures and temperatures of the injection process while maintaining the precise shape and dimensions of the part. Advanced control systems are used to monitor and adjust the injection parameters, such as temperature, pressure, and speed, to achieve the good conditions for producing parts with the required precision. Precision Injection Molding also often involves the use of specialized materials that offer the necessary strength, durability, and dimensional stability for the application.

The applications of these advanced injection molding techniques are vast, spanning across various industries. In the automotive industry, Shot Volume Injection Molding can be used to produce complex parts with uniform wall thickness, such as dashboards and structural components. SPC Injection Molding is beneficial for maintaining consistent quality in the production of automotive parts, such as door panels and exterior trim. Precision Injection Molding is crucial in the medical industry for the production of precision components, such as surgical instruments and implantable devices.

The demand for high-quality plastic components continues to grow, the adoption of advanced injection molding techniques like Shot Volume Injection Molding, SPC Injection Molding, and Precision Injection Molding becomes increasingly important. These methods not only improve the efficiency and quality of the manufacturing process but also enable the production of parts that meet the stringent requirements of various industries.

English

English 中文简体

中文简体 русский

русский