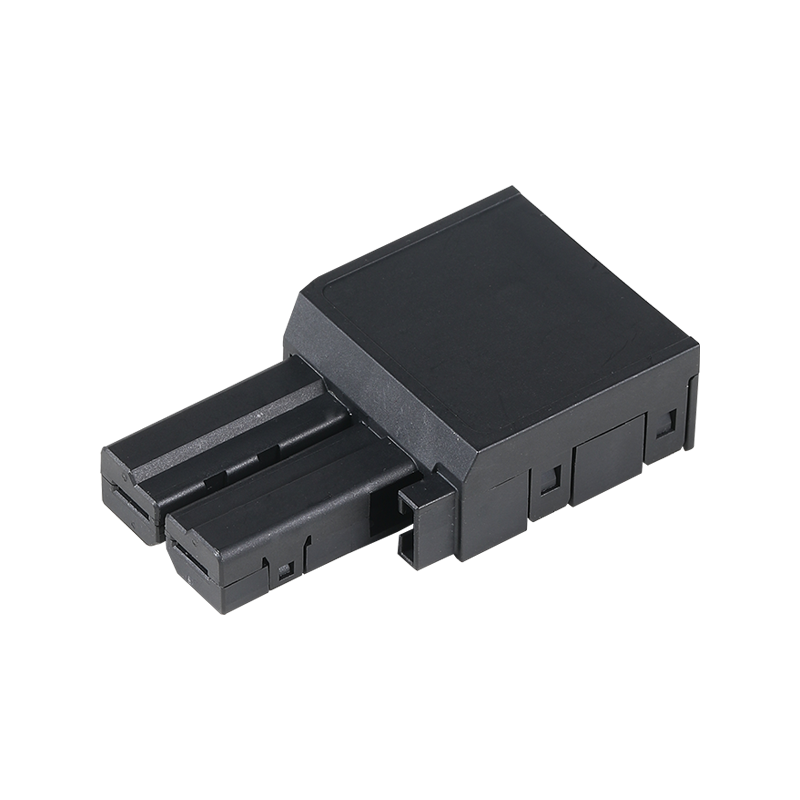

Plastic Plug-in Connector Series Components serve as vital elements within various industries, ranging from household appliances to computer communication and automotive sectors. These connectors facilitate seamless connections, ensuring efficient operations across a multitude of applications. In this comprehensive guide, we'll delve into the diverse categories and functionalities of these connectors, shedding light on their significance in modern technology.

Basic Overview

Plastic Plug-in Connector Series Components encompass a wide array of connectors designed to establish secure electrical connections. These connectors feature plastic housing, which not only ensures durability but also aids in insulation, making them suitable for diverse environments. With their plug-and-play functionality, these components simplify installation processes, thereby enhancing efficiency in various applications.

Key Features and Benefits

Plastic plug-in connector series components offer several key features and benefits that make them indispensable in various applications. These include:

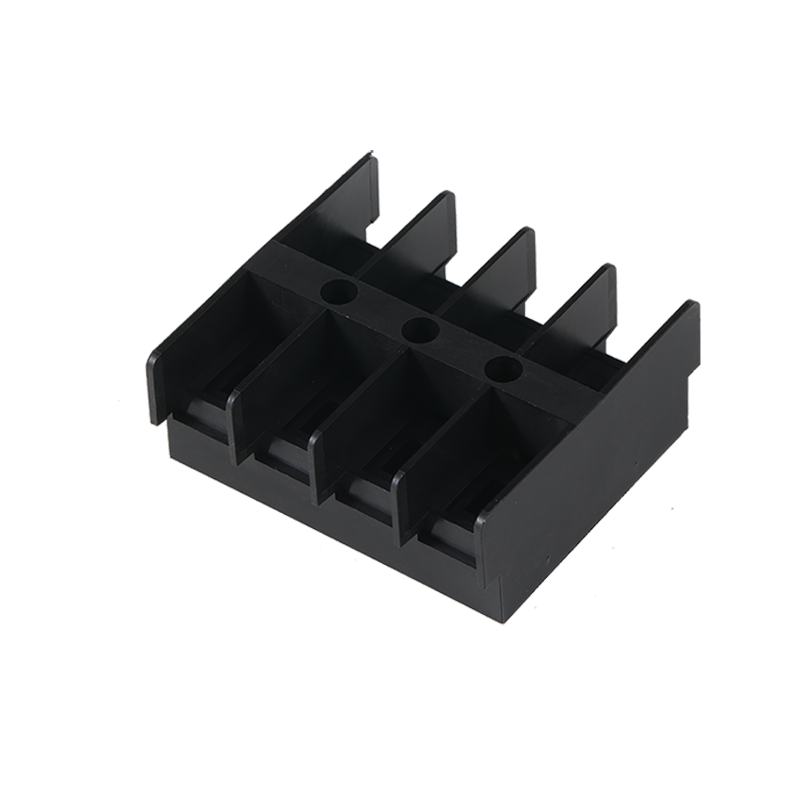

Durability: Constructed from high-quality plastics, these components are built to withstand environmental stressors, ensuring long-term reliability.

Versatility: Available in a variety of shapes, sizes, and configurations, these connectors cater to diverse application requirements, offering flexibility and adaptability.

Ease of Installation: Designed for plug-and-play functionality, these components facilitate quick and hassle-free installation, reducing downtime and labor costs.

Cost-effectiveness: Offering a good balance of performance and affordability, plastic plug-in connector series components provide a cost-effective solution for various electrical connectivity needs.

Customization and Compatibility

One of the key advantages of Plastic Plug-in Connector Series Components is their versatility and compatibility with various devices and systems. Manufacturers offer a range of configurations and specifications to suit specific application requirements. Additionally, these connectors can be customized to meet unique needs, ensuring seamless integration and good performance across different industries and applications.

Safety Standards and Compliance

Ensuring the safety of electrical connections is paramount, especially in sensitive applications such as household appliances and automotive systems. Plastic Plug-in Connector Series Components adhere to stringent safety standards and regulatory requirements to guarantee good performance and user safety.

Applications of Plastic Plug-in Connector Series Components

The versatility of plastic plug-in connector series components extends across various industries, playing a crucial role in enabling seamless communication and power distribution. Some key applications include:

Household Appliances: From refrigerators to washing machines, plastic plug-in connectors ensure efficient power delivery and control, enhancing the functionality and safety of household appliances.

Computer Communication: In the realm of computing, these connectors facilitate the interconnection of components within desktops, laptops, and servers, enabling data transfer and peripheral connectivity.

Automotive Systems: In the automotive sector, reliable connectivity is paramount for ensuring the smooth operation of vehicle systems. Plastic plug-in connectors withstand the rigors of automotive environments, enabling vital functions such as engine management, lighting control, and infotainment systems.

Industrial Machinery: In industrial settings, where reliability and durability are critical, plastic plug-in connectors provide a dependable solution for power distribution, control, and data transmission in machinery and equipment.

In conclusion, Plastic Plug-in Connector Series Components represent a cornerstone of modern connectivity solutions, offering reliability, versatility, and performance across various industries. From household appliances to automotive systems, these connectors play a vital role in enabling seamless communication and power distribution. With their extensive range of types and applications, they continue to drive innovation and efficiency in the ever-evolving landscape of electronic connectivity.

English

English 中文简体

中文简体 русский

русский