Connectors are indispensable components that facilitate the transfer of power and data between various devices. One such innovative connector that has gained prominence is the waterproof magnetic breakaway electrical connector. These connectors offer a unique combination of safety, reliability, and durability, making them ideal for a wide range of applications where water resistance and secure connections are paramount.

Waterproof magnetic breakaway electrical connectors are designed to operate in environments where exposure to water, moisture, or other liquids is a concern. The waterproofing feature is crucial for protecting the electrical connections from the corrosive effects of water, which can pilot short circuits, equipment failure, and even safety hazards. By preventing water ingress, these connectors ensure that electrical systems remain operational and safe in wet conditions, which is particularly important in outdoor applications, marine environments, and industrial settings where water exposure is common.

The magnetic breakaway feature of these connectors provides an additional layer of safety. It allows the connector to separate under excessive force, preventing damage to the connected equipment and protecting the integrity of the electrical connection. This mechanism is particularly useful in applications where connectors may be subjected to physical stress, such as in moving vehicles, more machinery, or in situations where accidental tugs or pull could occur. The magnetic breakaway design ensures that the connection remains secure until a predetermined force is applied, at which point it disconnects safely, preventing damage to the connector or the connected devices.

These connectors find use in a variety of applications due to their robust design and functionality. Some of the common uses include:

In outdoor lighting systems, waterproof magnetic breakaway connectors ensure that the electrical connections remain secure and safe, even in rainy or snowy conditions.

Boats, yachts, and other marine vessels require connectors that can withstand the harsh marine environment. These connectors protect the electrical systems from saltwater corrosion and the risk of short circuits.

In industrial settings, where machinery and equipment are often exposed to water, dust, and other contaminants, these connectors provide a reliable and safe means of connecting power and data lines.

For emergency vehicles and equipment, such as ambulances and fire trucks, these connectors ensure that critical systems remain operational even in wet conditions, which is vital for their performance during emergencies.

In wind turbines and solar panel installations, these connectors are used to connect power lines in a way that is resistant to the elements, ensuring the longevity and reliability of the energy generation systems.

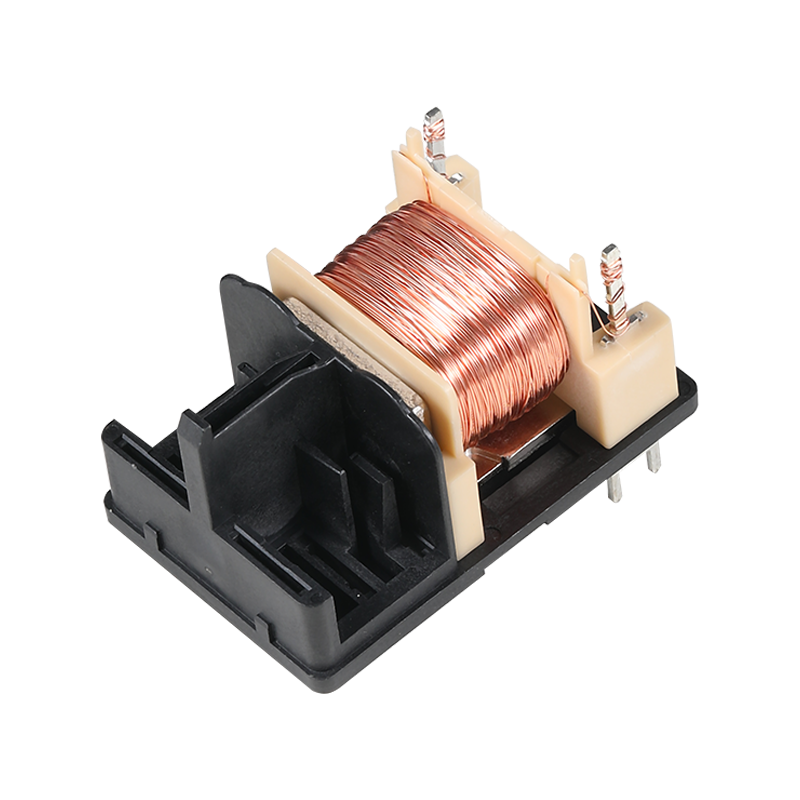

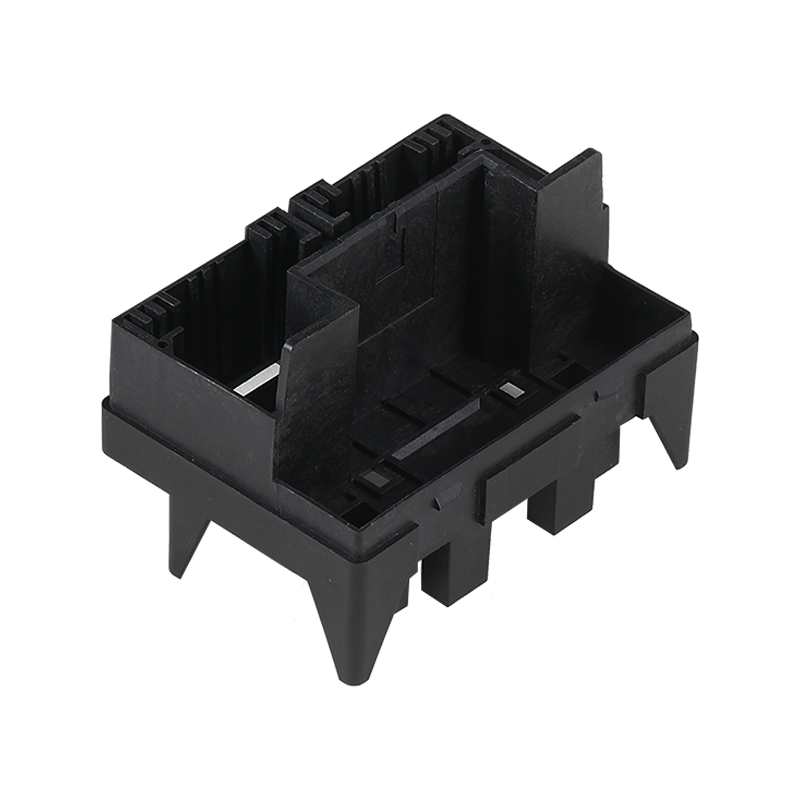

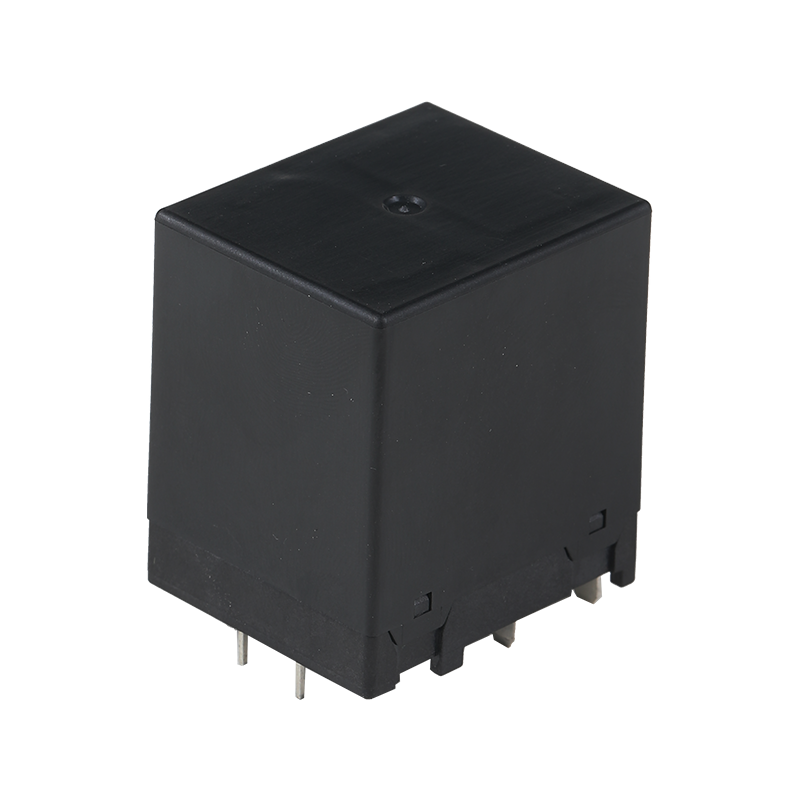

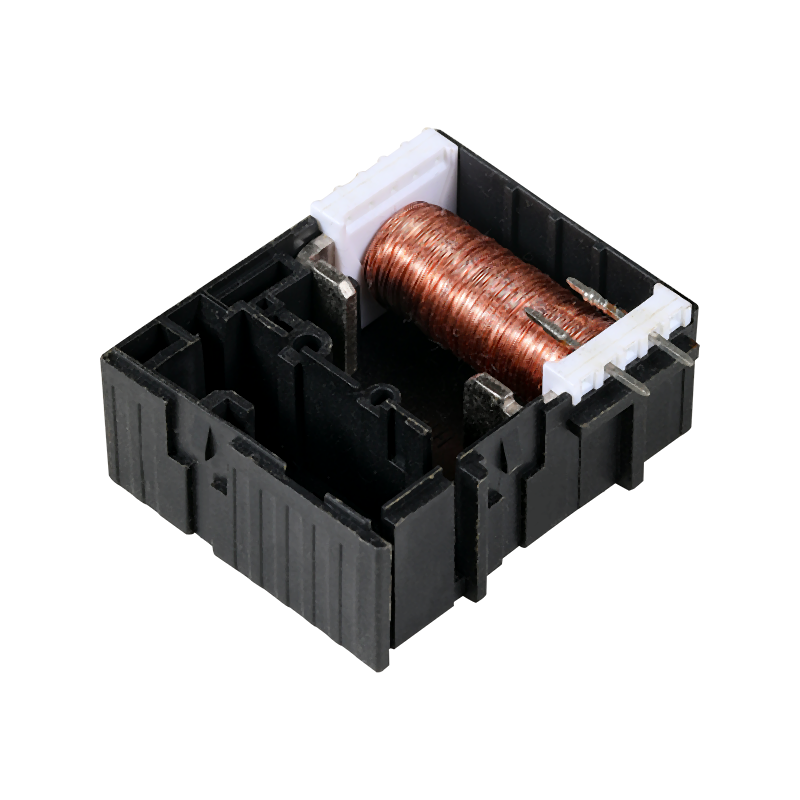

Waterproof magnetic breakaway electrical connectors are engineered with a focus on durability and reliability. They typically feature robust housing made from materials such as high-quality plastics or metals that can withstand harsh conditions. The magnetic components are designed to provide a strong connection until the breakaway force is exceeded, at which point they separate cleanly without damage. The connectors also include seal mechanisms, such as rubber gaskets or O-rings, to prevent water and debris from entering the connection points.

Proper maintenance is key to the longevity of these connectors. Regular inspections can help identify any signs of wear or damage, ensuring that the connectors continue to perform their function effectively. The durability of these connectors is also a significant advantage, as they are designed to withstand repeated connections and disconnections without losing their effectiveness.

Waterproof magnetic breakaway electrical connectors are a testament to the innovation in the field of electrical engineering. They offer a solution that combines safety, reliability, and durability, making them an essential component in a variety of applications.

English

English 中文简体

中文简体 русский

русский