Part connectors, also known as component connectors, are essential interfaces in electronic systems that facilitate the connection between various components. They are designed to ensure reliable signal transmission and power distribution within devices. These connectors come in a wide array of types, including PCB connectors for printed circuit boards, and are crucial for maintaining the integrity and performance of electronic equipment. Their design and materials are chosen to withstand various environmental conditions, ensuring durability and longevity in applications ranging from consumer electronics to industrial machinery.

Among the various types of connectors, hermetic circular connectors and PCB electrical connectors stand out for their reliability and versatility.

Hermetic circular connectors are designed to provide airtight and watertight connections, which are crucial in environments where moisture, dust, and other contaminants could compromise the integrity of electronic systems. These connectors are often used in applications where reliability is paramount, such as in aerospace, military, and medical equipment. The hermetic seal ensures that the internal components of the connector remain protected from the external environment, which is vital for maintaining the performance and longevity of the connected devices.

One of the key features of hermetic circular connectors is their ability to withstand bad temperatures and pressures. This makes them ideal for use in high-stress environments where conventional connectors might fail. The construction of these connectors often involves the use of materials like stainless steel and high-quality elastomers, which contribute to their robustness and durability.

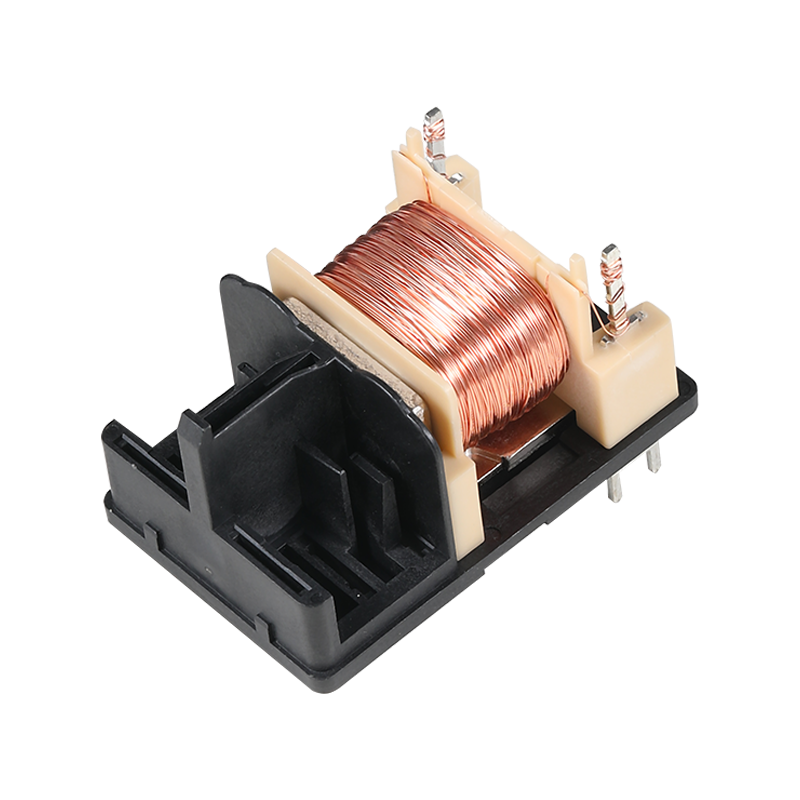

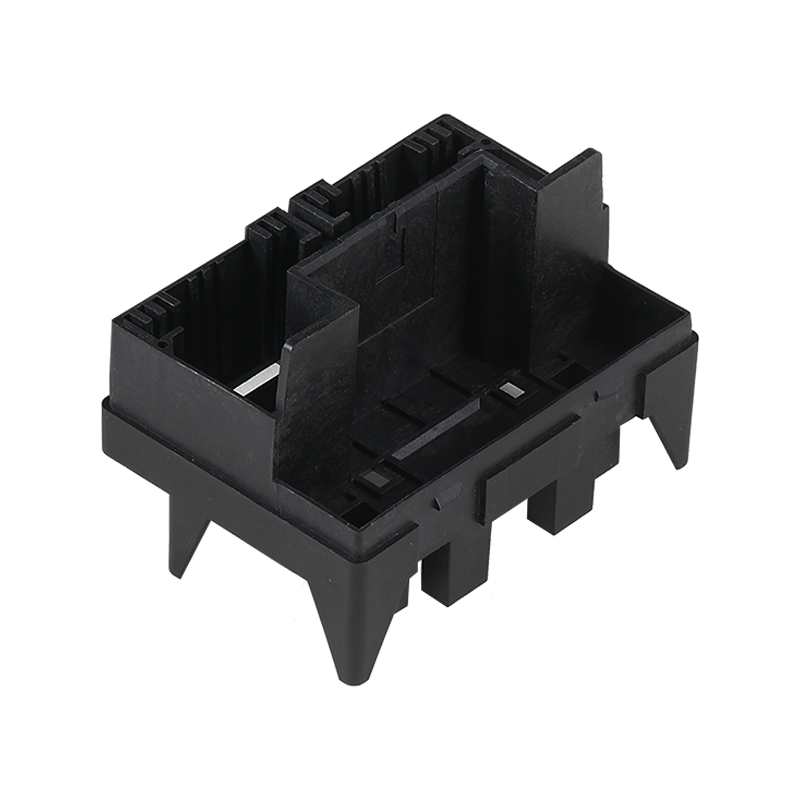

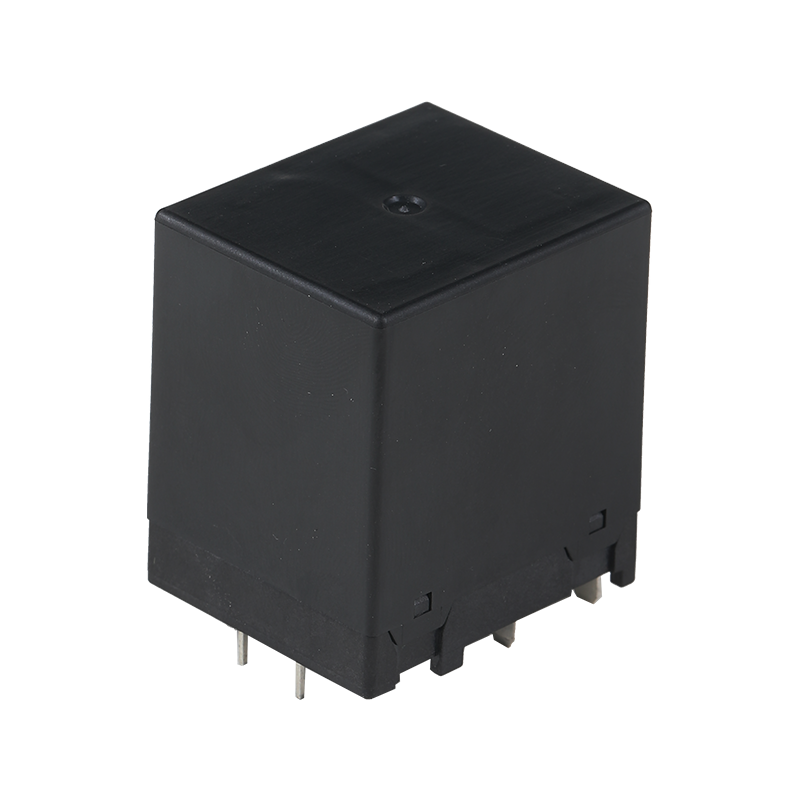

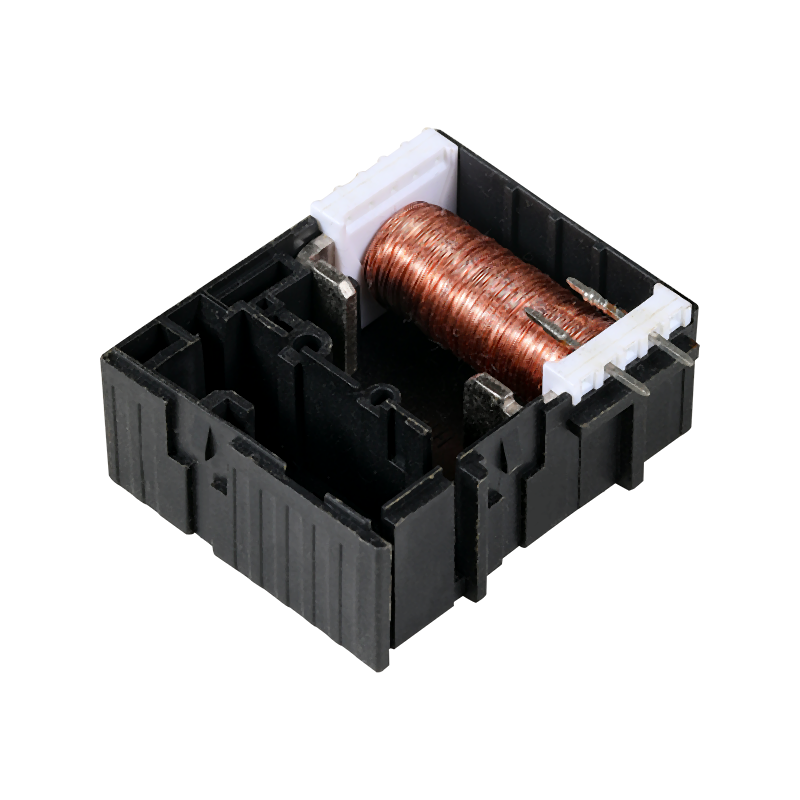

PCB electrical connectors are essential components in the assembly of printed circuit boards (PCBs). They facilitate the connection between the PCB and external devices or other PCBs, allowing for the transfer of electrical signals and power. These connectors come in a variety of forms, including through-hole, surface-mount, and edge connectors, each designed to meet specific design requirements.

The choice of PCB electrical connector depends on factors such as the density of the PCB, the type of signals being transmitted, and the space available for the connector. High-density connectors are often used in applications where space is at a premium, such as in smartphones and other compact electronic devices. These connectors must be able to handle a large number of connections in a small area, making their design and manufacturing a complex process.

Part connectors, which include both hermetic circular connectors and PCB electrical connectors, are critical to the overall performance of electronic systems. They must be able to withstand the rigors of daily use, as well as the challenges posed by environmental factors such as temperature fluctuations, humidity, and physical stress.

The reliability of part connectors is not just about their physical durability; it also involves their electrical performance. Connectors must have low resistance and high signal integrity to ensure that the data and power they transmit are accurate and efficient. This is particularly important in high-speed data transmission applications, where any loss of signal quality can pilot data corruption or system failure.

Hermetic circular connectors and PCB electrical connectors are integral to the functioning of modern electronics. They provide the necessary connections that enable devices to operate effectively and efficiently. As technology continues to advance, the demand for high-quality, reliable connectors will only increase. Manufacturers must continue to innovate and improve their connector designs to meet the evolving needs of the electronics industry.

English

English 中文简体

中文简体 русский

русский