Electrical connectors play a critical role in modern electronics and electrical systems. They ensure a reliable connection between various components, enabling the transmission of signals or power. Among the many types, electrical circuit connectors, electrical board connectors, and electrical connector parts are essential for the functionality of diverse applications.

Electrical circuit connectors are designed to establish and maintain secure electrical connections within a circuit. These connectors are commonly used in wiring systems, control panels, and electronic devices. They can be categorized into various types based on their functionality, including:

Plug and Socket Connectors: Often used in household and industrial wiring, these connectors allow easy disconnection and reconnection of circuits.

Terminal Blocks: These connectors are ideal for securing multiple wires in a controlled environment, providing a safe and organized connection.

Crimp Connectors: Designed for high reliability, these are attached to wires by compressing the metal around the conductor, ensuring small resistance.

The materials used in these connectors, such as copper or brass, are selected for their conductivity and durability. Protective coatings like nickel or tin are often applied to enhance resistance against corrosion and oxidation.

Electrical board connectors are specific to printed circuit boards (PCBs), serving as interfaces between the board and external components or systems. They facilitate the transfer of data, signals, or power within electronic devices. Common types include:

Pin Headers and Sockets: These connectors are widely used in microcontroller boards, allowing modules or shields to be easily attached and detached.

Edge Connectors: Found in devices such as memory cards and expansion slots, these connectors provide a streamlined method to link a PCB with another system.

Board-to-Board Connectors: These connectors join two circuit boards directly, enabling compact and efficient designs in devices such as smartphones and laptops.

Electrical board connectors require precision engineering to maintain a low profile while ensuring reliable performance. Factors such as pin alignment, contact resistance, and insulation are critical to their design and manufacturing.

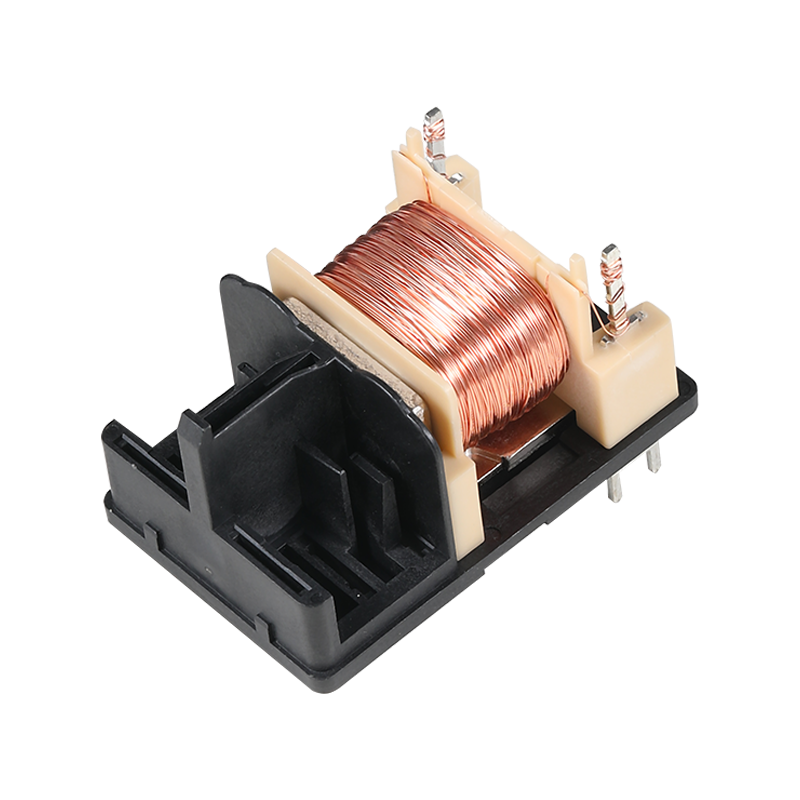

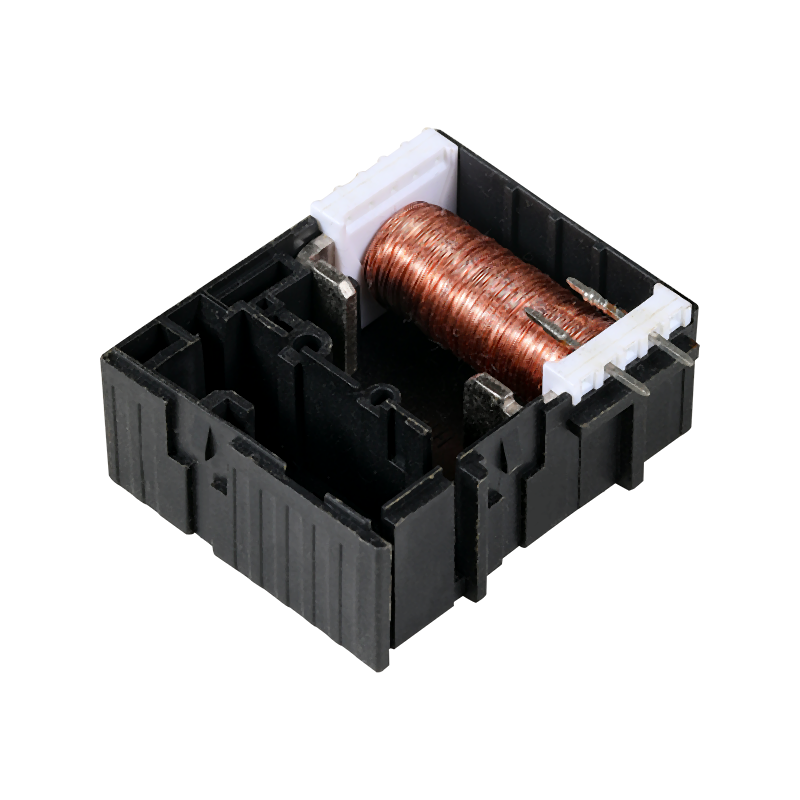

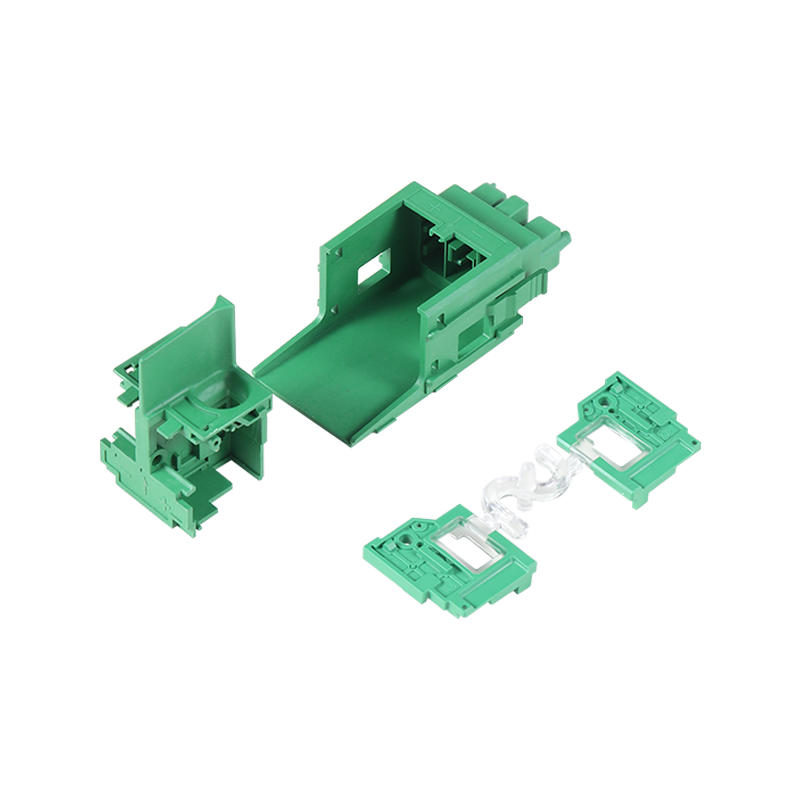

Electrical connector parts refer to the individual components that constitute a complete connector system. These parts are essential for customization, repair, or assembly of connectors and include:

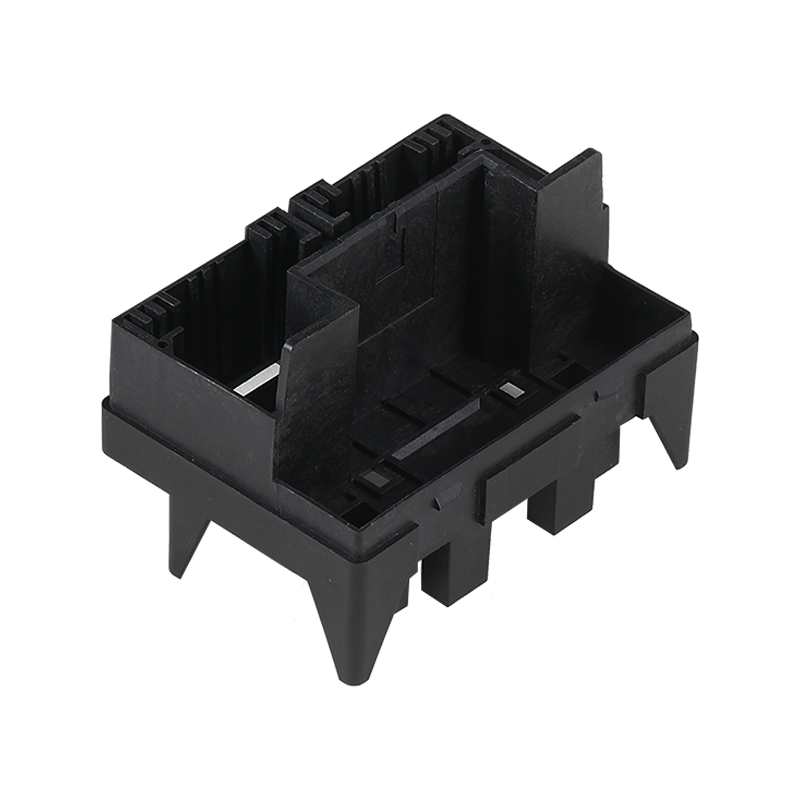

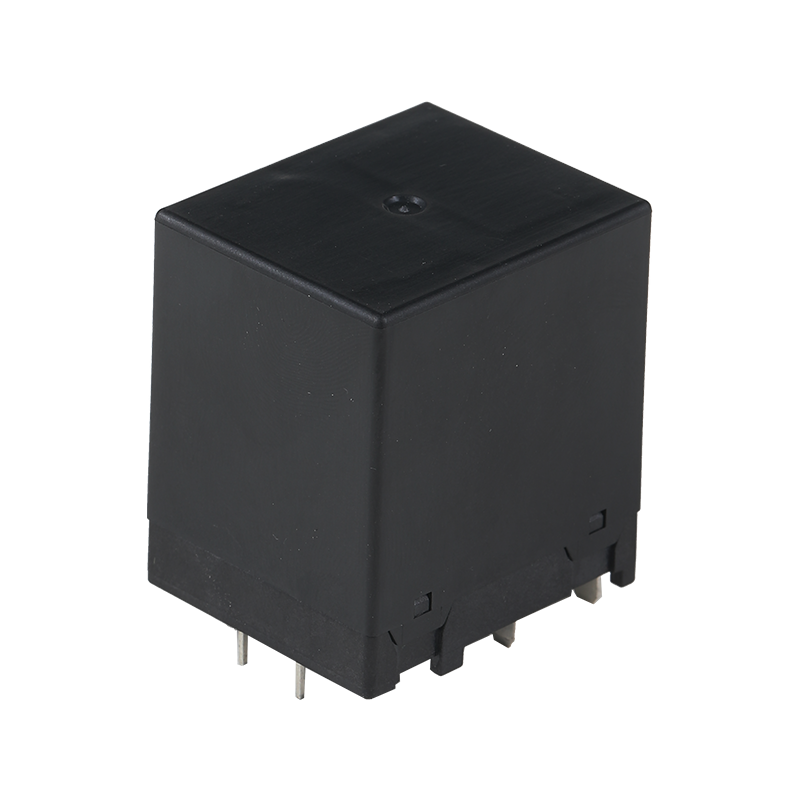

Housings: The outer casing that protects internal components and provides structural support. These are often made of plastic or metal to ensure durability and insulation.

Contacts: The conductive elements that establish the actual electrical connection. Contacts are typically fabricated from metals with high conductivity and may feature plating to resist wear.

Seals and Grommets: Used to enhance the environmental resistance of connectors, seals prevent the ingress of dust, moisture, and other contaminants.

Mounting Accessories: Items such as screws, clamps, or brackets that secure connectors in place.

These parts can be tailored to specific requirements, such as high-temperature resistance or waterproofing, depending on the application.

Electrical connectors are integral to industries such as automotive, telecommunications, aerospace, and consumer electronics. Their widespread use makes understanding their design and functionality essential for ensuring system reliability. Key considerations when selecting or designing electrical connectors include:

Voltage and Current Ratings: Ensuring the connector can handle the required electrical load without overheating or failure.

Environmental Conditions: Factors like temperature, humidity, and exposure to chemicals influence the choice of materials and protective features.

Ease of Installation: Connectors should be user-friendly, especially in applications requiring frequent assembly or disassembly.

Electrical circuit connectors, electrical board connectors, and electrical connector parts form the backbone of electrical and electronic systems. Their design, materials, and functionality directly impact the efficiency and reliability of the systems they serve.

English

English 中文简体

中文简体 русский

русский