In the intricate world of electronics, connectors play a pivotal role in establishing the link between various components. Among these, flexible printed circuit connectors, electronic board connectors, and mini connector components are essential for the seamless operation of electronic devices.

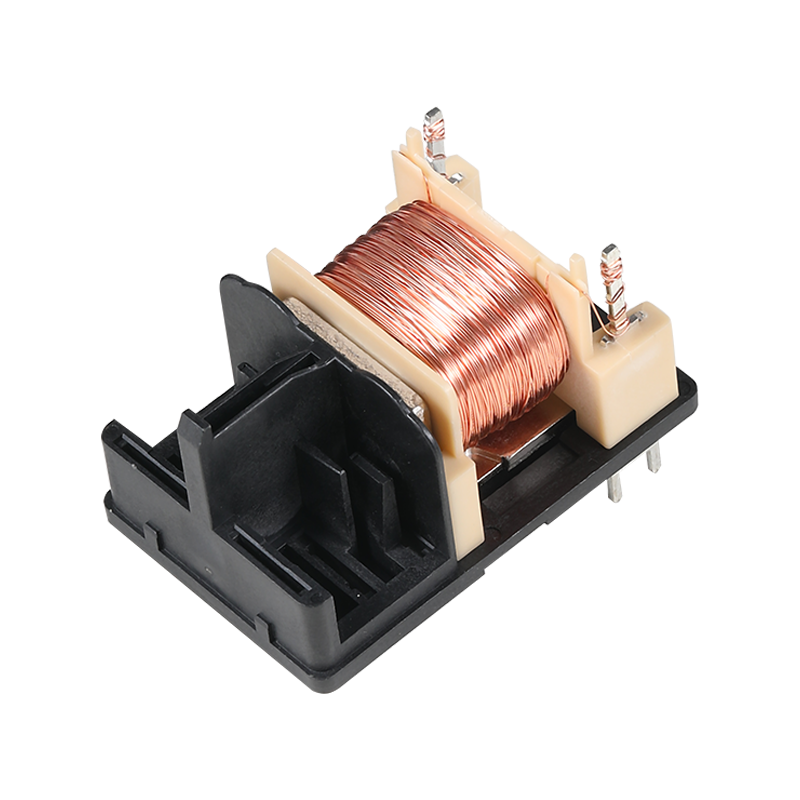

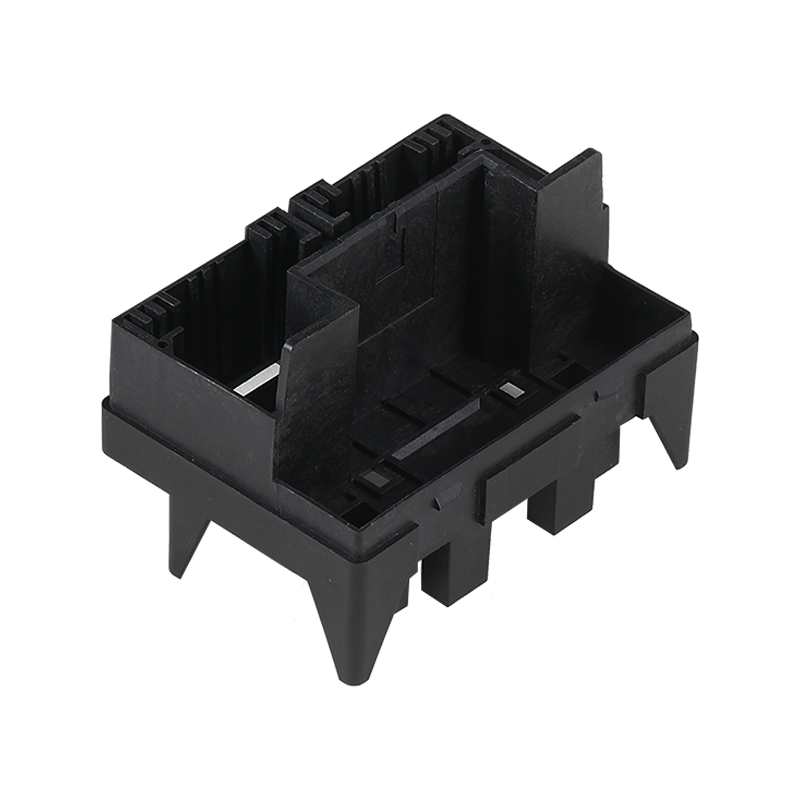

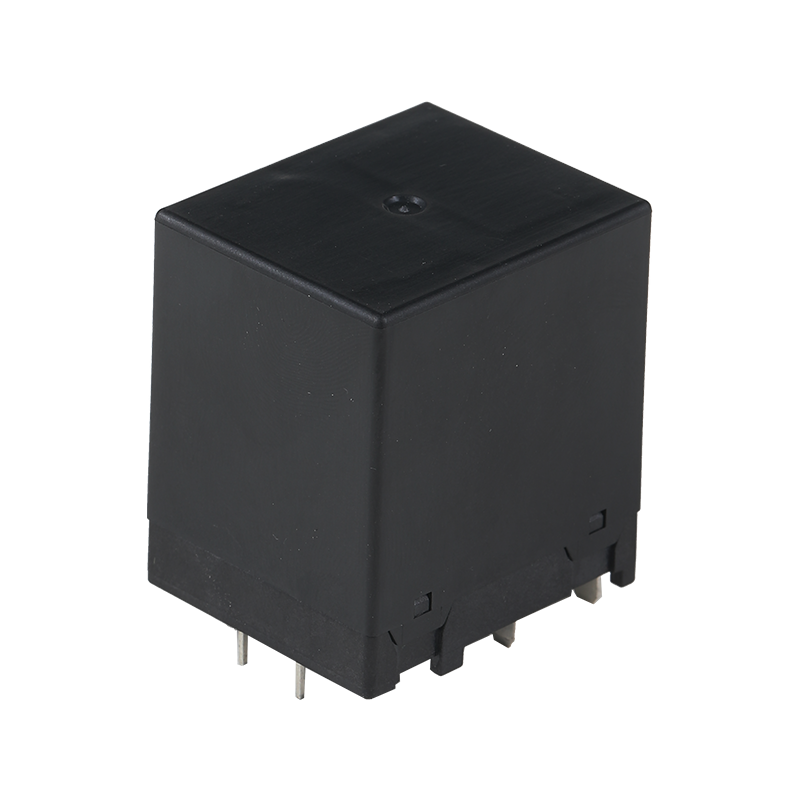

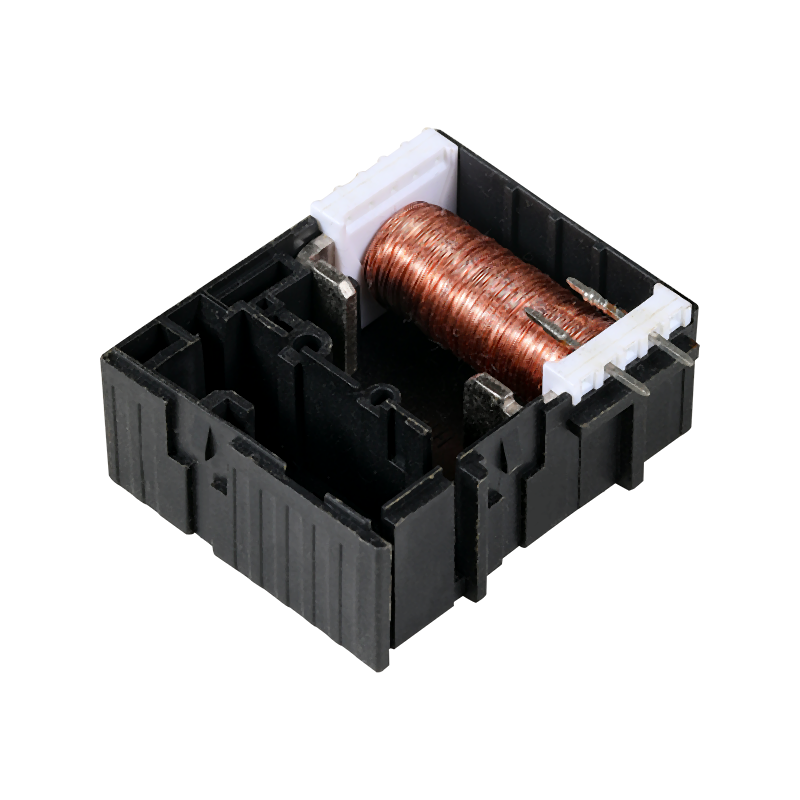

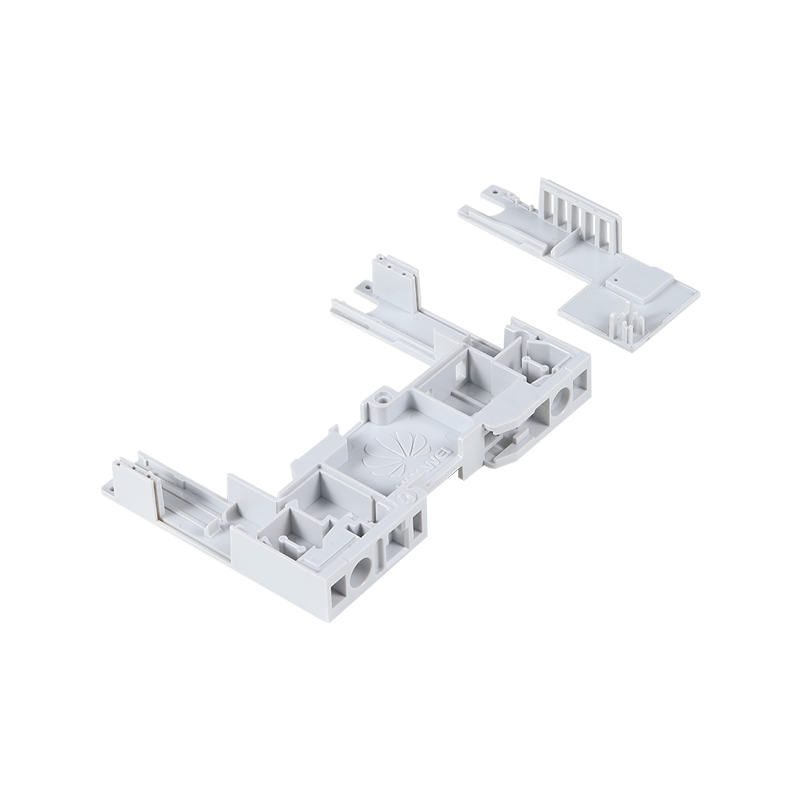

Connector components are essential in electronics for establishing secure and reliable connections between different parts of a circuit. They facilitate the transfer of electrical signals or power and come in various types, such as PCB connectors, cable connectors, and terminal blocks. These components are designed to withstand different environmental conditions and are crucial for the performance and longevity of electronic devices.

Flexible printed circuit connectors are designed to provide a reliable connection between rigid printed circuit boards (PCBs) and other electronic components. These connectors offer several advantages, such as flexibility, durability, and the ability to withstand repeated bending without damage. They are particularly useful in applications where space is limited or where components need to be connected in a flexible manner, such as in wearable technology or automotive electronics.

Electronic board connectors are the backbone of any electronic system, ensuring that the various components on a PCB can communicate effectively with each other. These connectors come in a wide range of types, including pin headers, socket connectors, and edge card connectors. They are designed to accommodate different pitch sizes and contact arrangements to fit the specific requirements of the electronic device. The reliability and performance of electronic board connectors are critical, as they directly impact the functionality and longevity of the device.

As technology advances, there is a growing demand for smaller, more compact electronic devices. This has led to the development of mini connector components, which are designed to fit into tight spaces while maintaining high performance. These connectors are commonly found in smartphones, tablets, and other portable devices where size and weight are critical factors. Mini connectors are engineered to be robust and reliable, even in the face of the harsh conditions often encountered in portable electronics, such as exposure to dust, moisture, and physical stress.

The applications of these connectors are vast, spanning across various industries. In the automotive sector, they are used for engine management systems, infotainment systems, and safety features. In consumer electronics, they are integral to smartphones, laptops, and gaming consoles. In industrial settings, they are used in robotics, automation, and control systems. The benefits of using these connectors include improved signal integrity, reduced size and weight, and enhanced durability.

Despite their many advantages, connectors face challenges such as signal interference, corrosion, and wear over time. To address these issues, manufacturers are developing innovative solutions, including the use of shielding to reduce interference, corrosion-resistant materials, and designs that small wear and tear. Additionally, advancements in manufacturing techniques are allowing for the production of connectors with higher precision and better performance.

We can expect to see further miniaturization, improved performance, and the development of new materials that can withstand the demands of next-generation electronics. The future of connectors is promising, with ongoing research and development aimed at meeting the needs of an ever-changing technological landscape.

In conclusion, flexible printed circuit connectors, electronic board connectors, and mini connector components are critical elements in the world of electronics. They enable the complex interplay of components within devices and systems, ensuring reliable performance and connectivity.

English

English 中文简体

中文简体 русский

русский