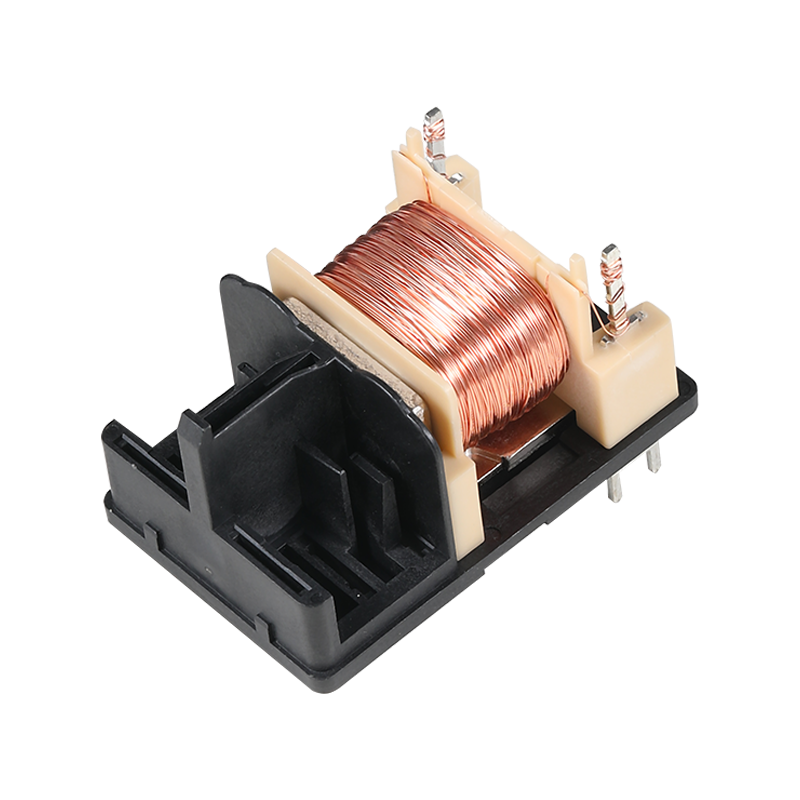

ODM thermal fuse connector Price

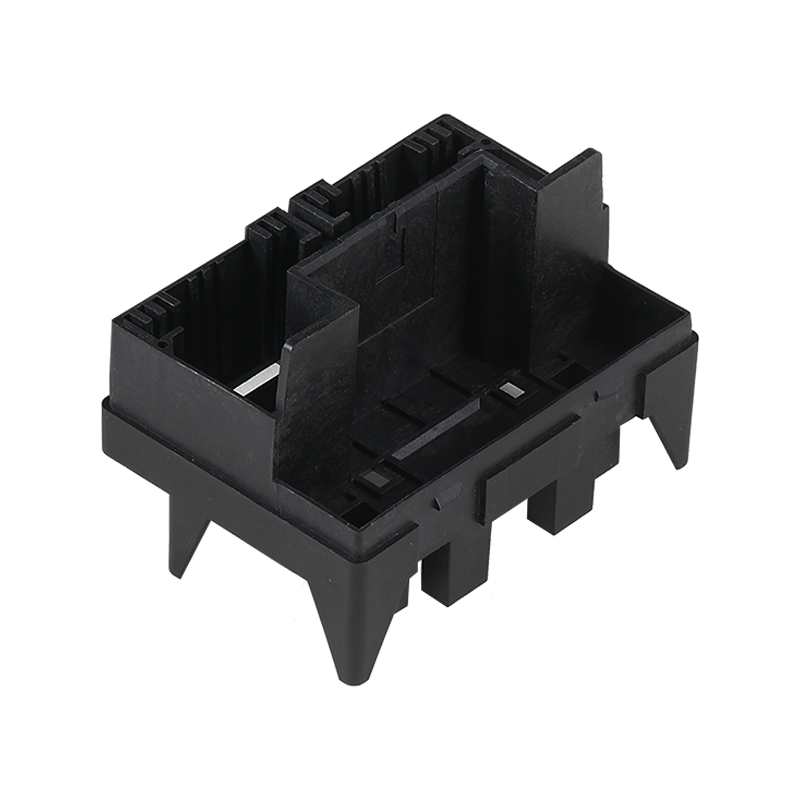

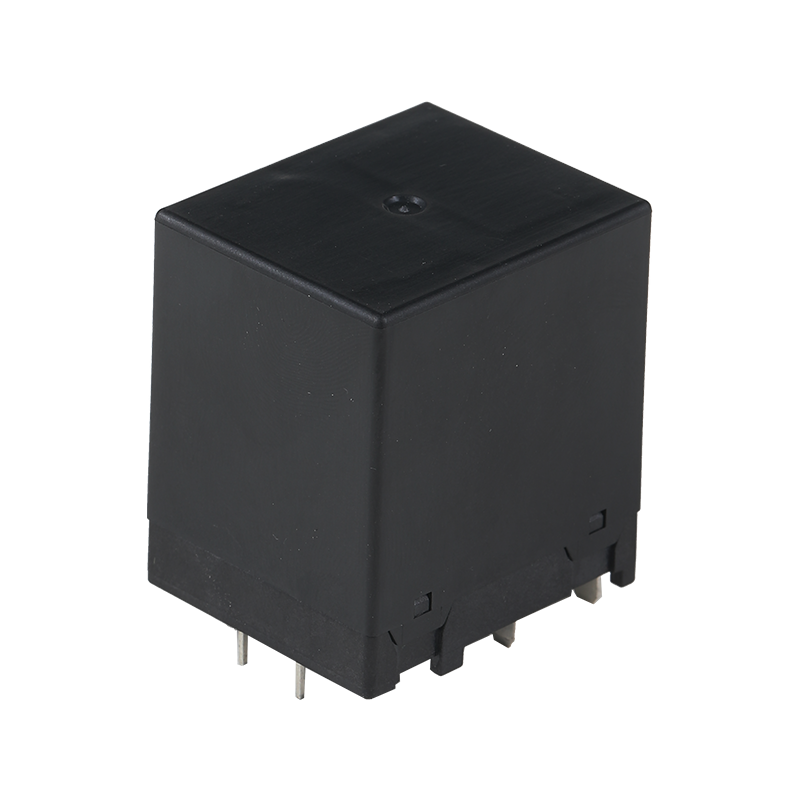

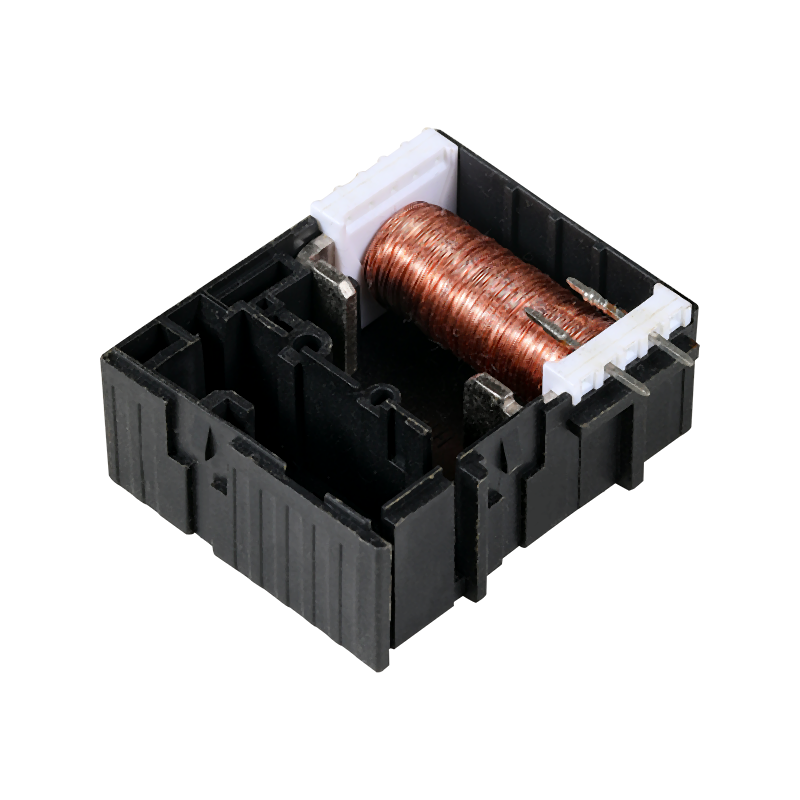

A thermal fuse connector is a crucial safety device designed to protect electrical circuits from overheating, which can lead to catastrophic failures or even fires. These connectors function by interrupting the flow of electricity when a predetermined temperature is reached, effectively acting as a safeguard for various appliances and electronic devices. The mechanism behind a thermal fuse connector is relatively simple yet highly effective. Inside the connector, there is a fusible element that melts or breaks when exposed to excessive heat. This action cuts off the electrical circuit, preventing further damage to the device and reducing the risk of fire.

The importance of thermal fuse connectors cannot be overstated. They are commonly found in household appliances such as hair dryers, coffee makers, and ovens, where overheating is a significant risk. For instance, in a hair dryer, if the air intake is blocked, the heating element can quickly reach dangerous temperatures. The thermal fuse connector intervenes by severing the electrical connection before the device can catch fire, ensuring user safety. This proactive approach to safety is what makes the connectors indispensable in modern electrical design.

In addition to their protective role, thermal fuse connectors are also cost-effective components. They are relatively inexpensive to manufacture and install, making them an attractive option for manufacturers looking to enhance the safety of their products without significantly increasing costs. The simplicity of the connectors means they can be easily integrated into a wide range of devices, providing a reliable solution for overheating issues.

However, the production and use of thermal fuse connectors also raise environmental concerns. The materials used in these connectors, such as plastics and metals, can contribute to environmental degradation if not disposed of properly. As electronic waste continues to be a growing problem globally, the lifecycle of the connectors must be considered. Manufacturers are increasingly being called upon to adopt sustainable practices, including using recyclable materials and ensuring that their products can be easily disassembled for recycling at the end of their life.

Moreover, the one-time use nature of many thermal fuse connectors poses additional challenges. Once the connector has activated due to overheating, it must be replaced, leading to increased waste. This aspect highlights the need for innovation in the design of thermal fuse connectors. Some manufacturers are exploring resettable thermal fuses, which can automatically restore functionality once the temperature drops. While these resettable options are less common, they represent a potential solution to reduce waste and enhance the sustainability of the connectors.

The environmental impact of thermal fuse connectors extends beyond their materials and disposal. The manufacturing processes involved in producing these connectors can also contribute to pollution and resource depletion. As the demand for electronic devices continues to rise, so does the need for thermal fuse connectors. This growing demand necessitates a careful examination of the environmental footprint associated with their production. Our company is increasingly focusing on minimizing their impact by adopting cleaner production methods and sourcing materials responsibly.

In conclusion, connectors play a vital role in protecting electrical circuits from overheating, ensuring the safety of countless devices we rely on daily. Their ability to cut off electrical flow in response to excessive heat is a simple yet effective safety measure. However, as we continue to integrate these connectors into our products, it is essential to consider their environmental implications. By prioritizing sustainable practices in the production and disposal of thermal fuse connectors, we can help mitigate the negative impacts associated with electronic waste and contribute to a more sustainable future. As technology evolves, so too must our approach to safety and environmental responsibility in the design and use of thermal fuse connectors.

English

English 中文简体

中文简体 русский

русский