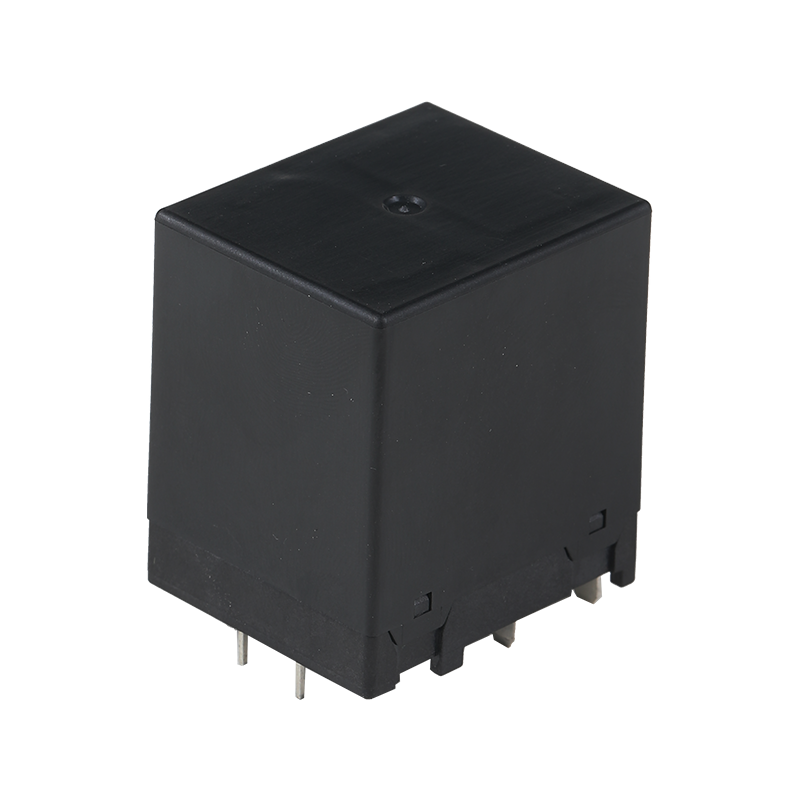

High current non-magnetic connectors are designed to handle substantial electrical currents without the hindrance of magnetic interference, ensuring efficient power transmission and good performance in various applications.

High current non-magnetic connectors are essential in applications where large amounts of electrical power need to be transferred with small loss and without the complications of magnetic interference. These connectors are preferred in high-power environments, such as in industrial machinery, power generation facilities, and heavy-duty transportation systems, where reliability and efficiency are paramount.

Features of High Current Non-Magnetic Connectors:

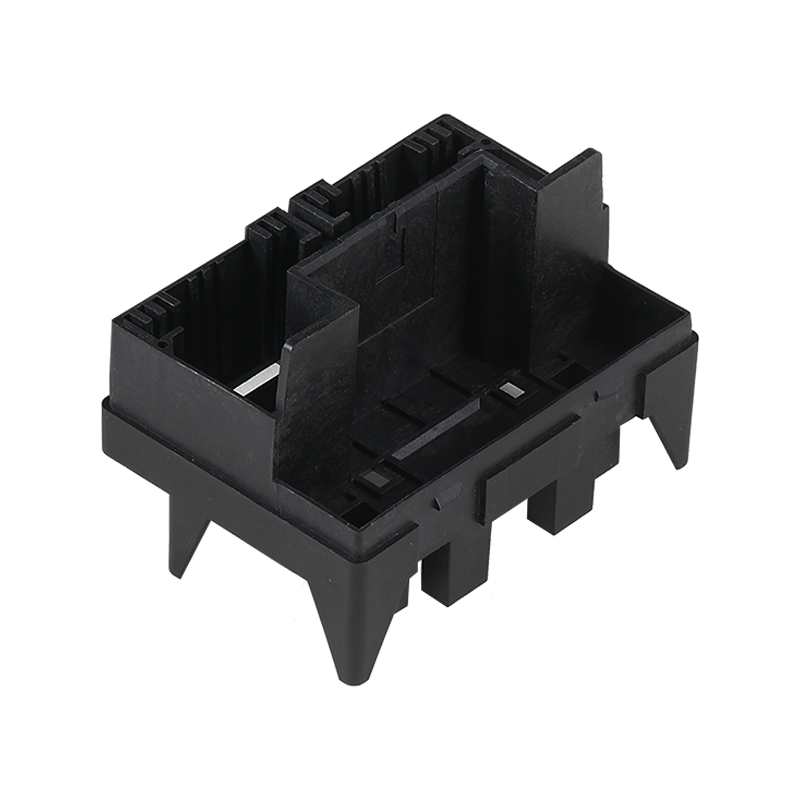

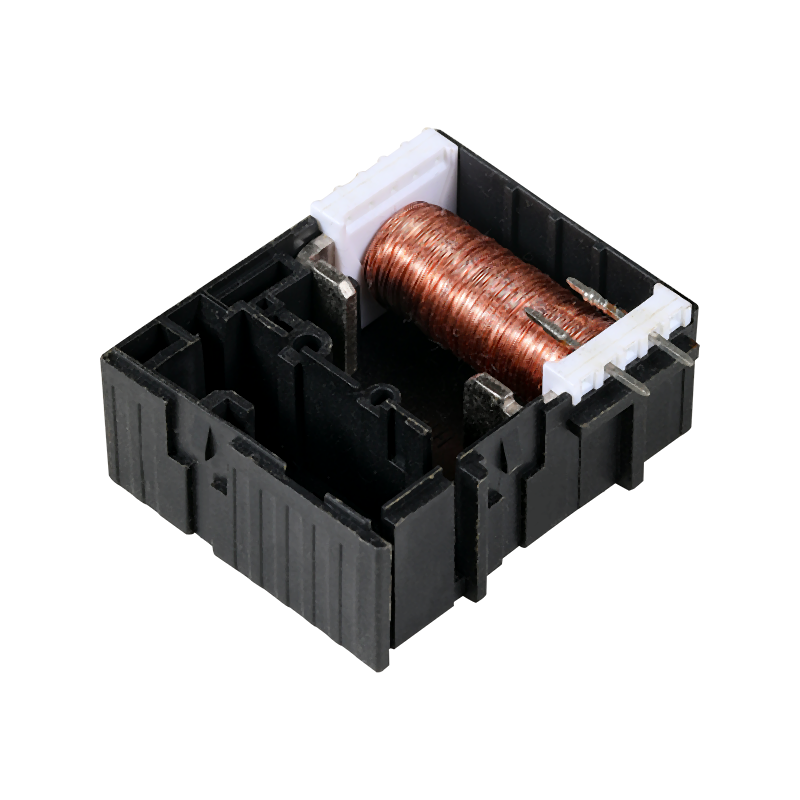

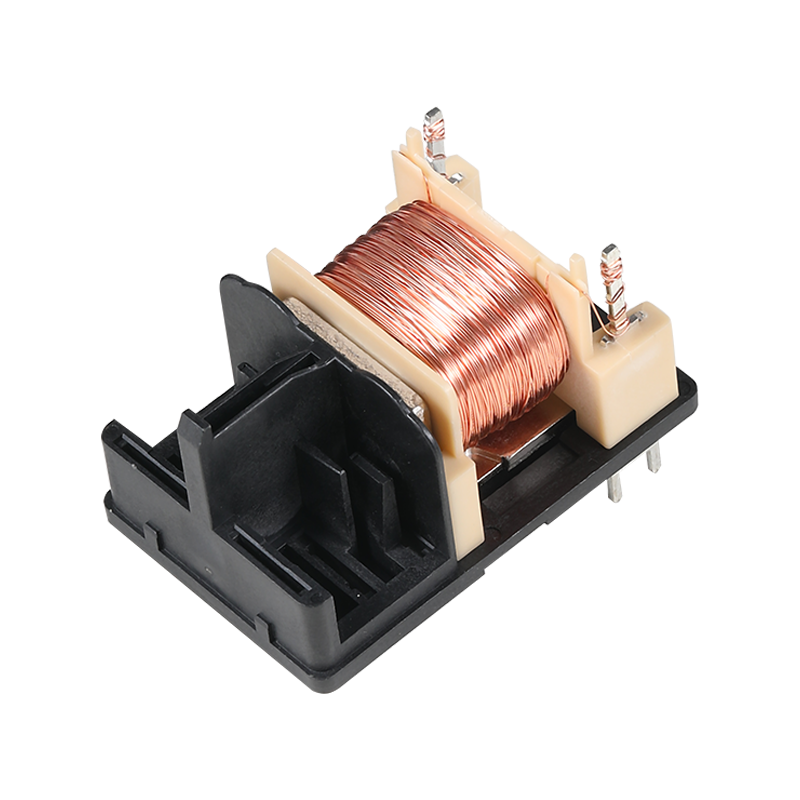

Material Selection: The primary feature that distinguishes high current non-magnetic connectors is the choice of material. Non-magnetic materials like aluminum or certain alloys are used to prevent the generation of magnetic fields that could interfere with the flow of current or the operation of nearby electronic devices.

High Current Capacity: These connectors are engineered to handle high currents, which means they have a larger cross-sectional area for the conductive paths, reducing resistance and heat generation.

Durability: To withstand the rigors of high-power applications, these connectors are made from robust materials and are designed to resist corrosion, wear, and environmental factors such as temperature fluctuations and humidity.

Safety: Safety is a critical feature, with high current non-magnetic connectors often incorporating features like built-in circuit breakers or fuses to prevent overloads and protect the connected equipment.

Ease of Use: Despite their robust construction, these connectors are designed for ease of use, with quick-connect and disconnect mechanisms that facilitate regular maintenance and service.

Applications of High Current Non-Magnetic Connectors:

Industrial Machinery: In industrial settings, high current non-magnetic connectors are used to power large machines and equipment, ensuring efficient energy transfer without the risk of magnetic interference affecting sensitive electronics.

Power Generation: Power plants and substations rely on these connectors for the transmission of electricity from generators to the grid, where high currents and the absence of magnetic fields are crucial.

Electric Vehicles: The electric vehicle (EV) industry utilizes high current non-magnetic connectors for charging stations and the internal connections within the vehicles themselves, providing a safe and efficient means of transferring the high currents required for rapid charging and operation.

Renewable Energy: Solar farms and wind turbines use these connectors to manage the high currents generated by these renewable energy sources, ensuring that the power is transferred efficiently to the storage systems or the grid.

Marine Applications: In the marine industry, high current non-magnetic connectors are used in ships and submarines for power distribution, where the risk of magnetic interference with navigation systems must be smalld.

With the increasing focus on renewable energy, electric mobility, and the need for more efficient power management in industrial applications, these connectors will play a vital role in the future of electrical systems.

In conclusion, high current non-magnetic connectors are a critical component in the world of power transmission. Their ability to handle high currents without magnetic interference makes them indispensable in a variety of high-power applications. As the world moves towards more sustainable and efficient energy use, the role of these connectors is set to become even more significant.

English

English 中文简体

中文简体 русский

русский