Solid-state static relays and switches which replace traditional mechanical relays and switches, operate using semiconductor components to provide faster response times and increased durability.

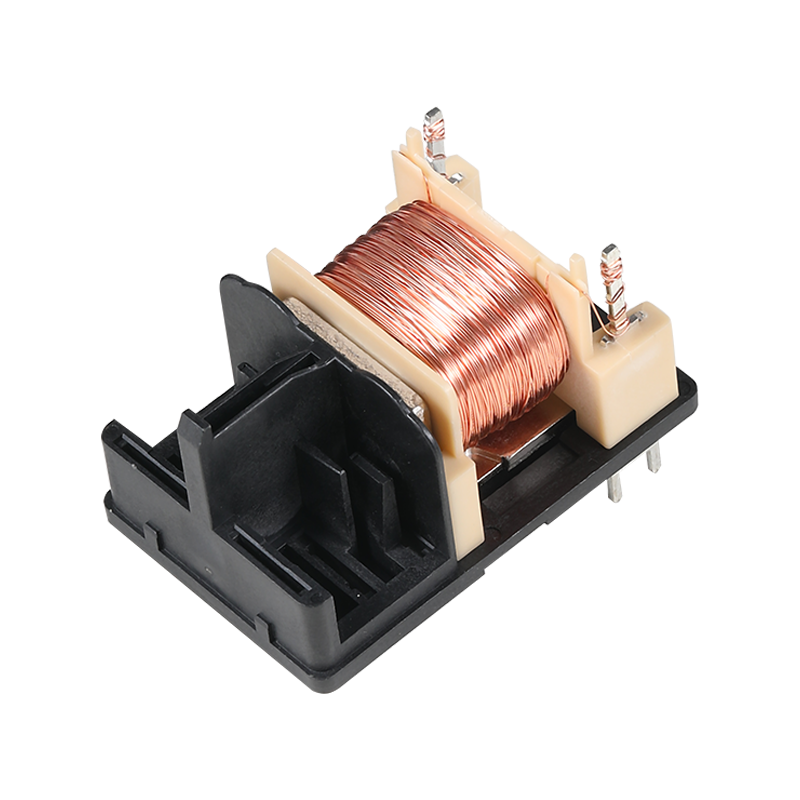

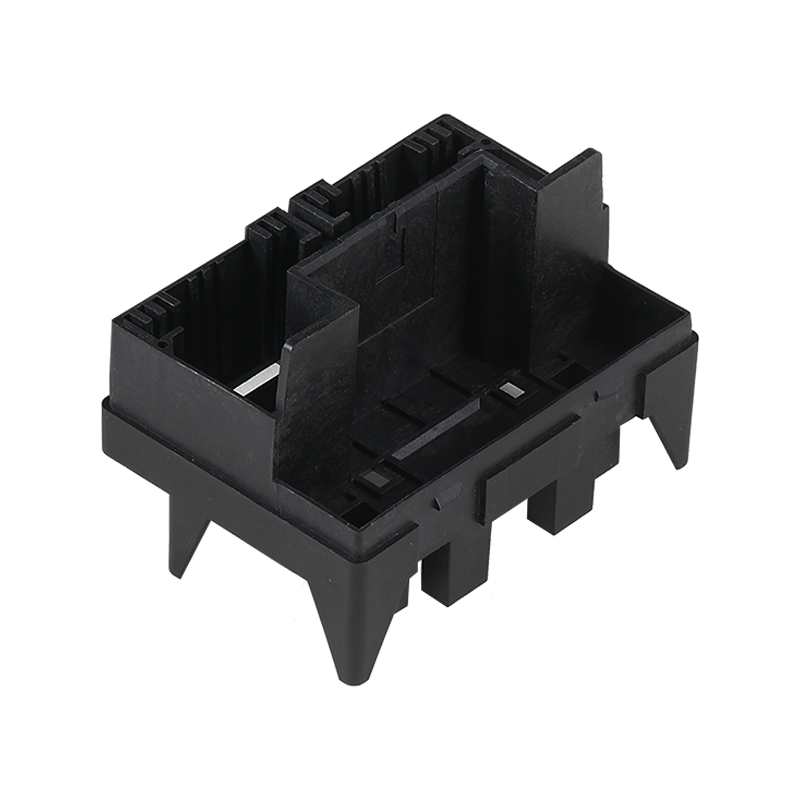

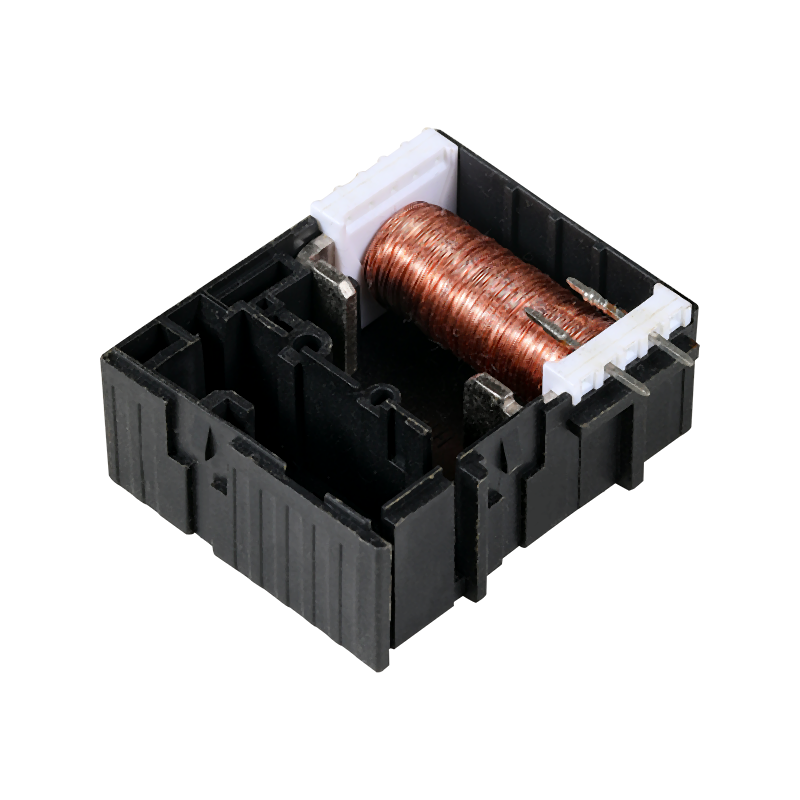

Solid-state static relays are made up of three primary sections: the input circuit, the control circuit, and the output circuit. Each section is designed to perform specific functions that contribute to the device’s overall performance:

The input circuit is the interface between the control signal and the relay. It detects low-level signals from control systems, such as microcontrollers, and converts them into appropriate signals for triggering the relay. Components such as optocouplers or phototransistors are often used to electrically isolate the input and output circuits, ensuring safety and preventing interference.

The control circuit processes the input signal and determines how the relay operates. It includes components such as logic gates, diodes, and capacitors that regulate the timing and activation of the output circuit. The control section ensures that the relay performs its switching function accurately, even under varying operating conditions.

The output circuit performs the actual switching operation, connecting or disconnecting the load from the power source. Semiconductor devices like thyristors, triacs, or MOSFETs are commonly used here, offering high-speed switching capabilities and low energy loss.

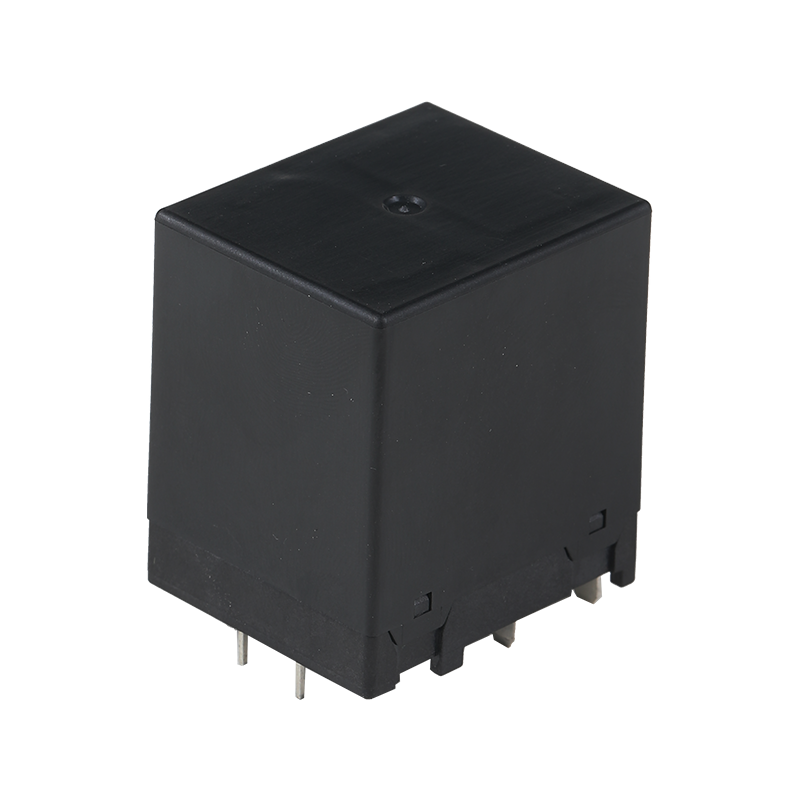

Solid-state relays provide several benefits compared to their mechanical counterparts. They have no moving parts, which eliminates issues like wear and tear, extending their lifespan significantly. This characteristic also makes them less prone to failures caused by vibration or mechanical stress.

Additionally, solid-state relays operate silently, making them suitable for applications where noise reduction is important. They also provide faster switching speeds, which are essential for applications requiring precise control over power delivery.

These devices are widely used in various industries due to their versatility and efficiency. Some common applications include:

Solid-state relays are used to control machinery, conveyor belts, and robotic arms. Their high reliability ensures consistent operation in demanding environments.

In lighting systems, these relays enable smooth dimming and on/off control without mechanical wear. This makes them suitable for commercial and residential lighting systems.

Solid-state relays are employed in heating, ventilation, and air conditioning (HVAC) systems to precisely control fans, compressors, and pumps.

In power supply systems, solid-state relays help manage overvoltage, Undervoltage, and short-circuit conditions by providing rapid response times.

These relays are utilized in telecom equipment to control signal routing and ensure reliable data transmission.

Solid-state switches are closely related to relays but serve slightly different purposes. While relays are primarily designed for isolation and control of power, switches are focused on directly controlling the flow of electrical current within a circuit.

Solid-state switches use similar semiconductor components as relays, such as MOSFETs or IGBTs, to achieve efficient and precise switching. These devices are favored in applications requiring high-speed operation and small energy loss.

When designing or selecting solid-state relays or switches, several factors must be considered to ensure compatibility with the intended application:

Devices must be rated to handle the voltage and current levels of the circuit without overheating or failure.

Heat dissipation is crucial for solid-state devices. Adequate cooling mechanisms, such as heat sinks or cooling fans, should be implemented to prevent overheating.

Electrical isolation between the input and output circuits is essential for safety and to prevent signal interference.

The switching speed of the device must align with the demands of the application, especially in high-frequency or precision-controlled systems.

The type of load, whether resistive, inductive, or capacitive, affects the selection of components for the relay or switch. For instance, inductive loads require devices with snubber circuits to manage voltage spikes.

English

English 中文简体

中文简体 русский

русский