Thank you for your attention and support to our company. We look forward to working together to create a better future.

Thank you for your attention and support to our company. We look forward to working together to create a better future.

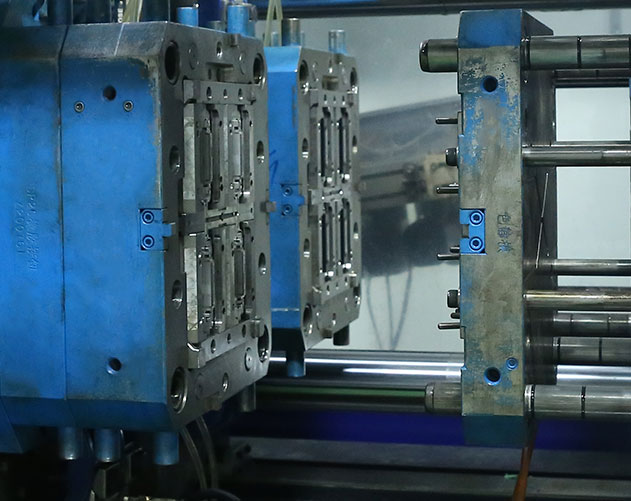

We are honored to showcase our company's outstanding strength in the field of mold processing to you. As a leading mold manufacturer in the industry, we are committed to providing high-quality and high-precision mold products to meet the diverse needs of customers, with a monthly mold processing capacity of about 50 pairs.

With this advanced equipment, professional team, and rigorous quality management system, our company has achieved significant achievements in the field of mold processing. We have established long-term and stable cooperative relationships with numerous well-known enterprises, providing them with high-quality mold products and technical support. We firmly believe that with our strength and experience, we can provide you with satisfactory products and services.

Essentially, the EDM process and WEDM have the same working principle. They all use spark machining to remove material, and different applications require different EDM manufacturing processes.

Wire EDM offers free range of motion, better parameter adjustability, axis control and the ability to machine different shapes using the same tool (i.e. wire). Traditional EDM relies on differently shaped tools, which often have a limited range of motion and are slow when processing tapered designs and complex shapes.

Electrodes: Common EDM uses diamond-shaped, circular, cylindrical or disc-shaped tool electrodes. The electrode translates along 3 axes, generating sparks and removing material on contact with the workpiece.

Wire-cut electric discharge machining uses thin wires with electrodes and workpieces immersed in a dielectric fluid that guides sparks and removes debris.

Accuracy: Traditional EDM is not as accurate as wire-cut EDM. This is mainly because disc or diamond-shaped electrodes are manufactured on CNC machine tools, which limits their accuracy and the accuracy of the tools.

The diameter of wire EDM can be less than 0.002 mm, which gives it an advantage in accuracy.

Electric spark machine is a type of equipment that uses the principle of electrical discharge to perform precise material processing, widely used in the manufacturing of complex parts. It achieves fine cutting and shaping of materials through spark discharge to meet the requirements of high-precision machining. This article will provide a detailed introduction to the electric spark machine structure and operational steps to offer you a comprehensive understanding.

Two types of side repair programs are planned for the CNC sparking machine. For rectangles with clear edges and corners, use a flat-bottomed side repair program, and for round or multi-curved ellipses, use a flat-bottomed round side repair program. During the side repair process of the CNC sparking machine, the electrode moves and feeds to the workpiece as a single point of sight. At this moment, the east and west electrodes move from the center to the outside, from top to bottom, and are actively controlled by CNC, that is, the three-axis linkage. This kind of motion method of CNC sparking machine has advantages of being unlikely to deposit carbon, simple chip removal and exhaust, no formed arc, and high production rate. X-axis lateral processing of split cavity by CNC sparking machine has high mold clamping accuracy, and its production rate comparable to Z-axis downward processing has improved a lot.

The CNC sparking machine has also made special improvements in the electronic control part. When an arc or false short circuit is found, the pulse power supply is immediately blocked, and the energy supply to the cavity is stopped. The electrode temperature will not continue to rise, and thus it will decrease the possibility of a fire.

The CNC sparking machine selects a good low-voltage pulse method after high-voltage breakdown, and the pulse width is flat. Practice has proved that this pulse method further reduces the electrode loss.

In terms of practical performance, CNC sparking machine gives users better experience and has higher efficiency than traditional electrical discharge machine does. The CNC sparking machine is more intelligent and can save labor. It is these characteristics of the CNC sparking machine that enable the product to be favored by more users.

CNC is the abbreviation of "computer numerical control", CNC machining is a kind of manufacturing process that instructs the operation of equipment and tools through programmed computer. This process can control various complicated machinery, such as CNC milling machine, CNC lathe, CNC laser machine, water jet machine, electric discharge machine (EDM), to complete the three-dimensional cutting task.

After activating the CNC system, the product file will be programmed into the software and assigned to the corresponding tools and machinery. These tools and machinery will perform the specified cutting tasks. The CNC machining process includes the following stages:

- Design CAD Model

- Convert CAD file to CNC program

- Prepare CNC machine and tools

- CNC Machining operations

CNC Milling: Use a multi-point rotating tool to remove material from the workpiece. Basic mills consist of a 3-axis system (X, Y and Z), which is still one of the most popular and widely used machining processes. In 3-axis machining, the workpiece remains fixed, and the rotating tool cuts along the x, y, and z axes. Meanwhile, most newer mills can accommodate two additional axis, 4-axis CNC machining and 5-axis CNC machining have higher versatility, and they are often used in the production of high-precision parts.

CNC Turning: Use a single-point cutting tools to remove material from the rotating workpiece. In CNC turning, the CNC machine, typically a lathe or turning machine, feeds the cutting tool in a linear motion along the surface of the rotating workpiece, removing material around the circumference until the desired diameter is achieved. Most CNC lathes consist of two axis, X and Z.