Mold Making

We provide Design for Manufacturability (DFM) feedback to help optimize your mold production design. Our team can review your design and provide recommendations to improve manufacturability, reduce costs, and ensure successful mold production.

Start mold quotation

Mold manufacturing process

Create a drawing

The first step is to obtain or create the design of the part to be formed, including all necessary dimensions, features, and specifications.

DFM

Design for Manufacturability (DFM) can optimize the design of parts or products to enhance their manufacturability in mold manufacturing.

Material selection

Choose appropriate mold materials based on specific applications, such as tool steel, aluminum, or other materials.

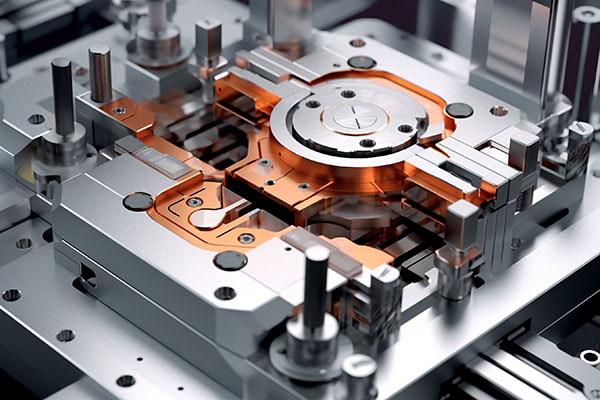

Production mold

The mold cavity and core are processed or formed using CNC machining or other techniques according to design specifications.

Surface Treatment

The surface of the mold in contact with the molten material is treated to improve demolding and reduce friction.

mold assembly

All mold components, including cavities, cores, inserts, and cooling channels, are assembled into the mold frame.

Sample validation

After assembly, the mold undergoes testing and validation to ensure functional and dimensional accuracy.

Used for mass production

Continuously monitor the performance of molds during the production process to ensure consistent quality of parts.

Design Software

Prepare for mold manufacturing

Conduct a Feasibility Analysis

We complete a feasibility analysis based on a Design for Manufacturing (DFM) report. We then share our feedback with the client and offer useful suggestions to prevent errors during the production phase. Identifying problems in advance gives us the information we need to correct potential glitches straightaway. That reduces total costs and allows us to craft products of exceptional quality.

Complete a MoldFlow Simulation

Using the latest MoldFlow software, we can determine the ideal position for a mold and the optimum temperature control before producing plastic parts. MoldFlow simulation is an essential component of the concept phase. It predicts the physical activity of plastic parts. Simulating the production phase before actual production can identify and prevent issues with weld lines, air pockets, and dents.

Execute a Filling Analysis

Using state-of-the-art computer-aided design (CAD) software and computer-aided engineering (CAE) technology, we can accurately simulate an injection molded part before installing it and predict the fill status. Uneven mold fillings can change the shape of the finished part. An early MoldFlow analysis keeps that from happening.

You can obtain injection molding quotations online,

or contact usimmediately at: [email protected]

Work With Us

Online quoting

DFM

Prototyping

Structure Design

Mold Making

On Trial

Logistics

After sales

More professional services

Strategic partnering with clients

Strategic partnering with clients is crucial for the success of any joint project. When you talk, we listen. Only by listening can we fully understand your needs. Only by fully understanding your needs can we fulfill them.

Ongoing client communication is essential. If there are hurdles along the way, we can troubleshoot and problem-solve together and thereby achieve goals faster.

Mold design optimization

Mold design optimization is what we offer. Because we’re specialists in the field with decades of experience and highly developed expertise, we excel at what we do. Our team of accomplished engineers has the confidence and ability to implement effective solutions for clients.

With optimization, we achieve high levels of efficiency and productivity. As a result, we can complete a plastic molding project for our customers at a significantly reduced cost.

Using advanced technology, we can spot potential problems and correct them before moving the project into production. That reduces costs in the later project phases.

One-Stop Services

Maximizing your investment is our goal. Our expenditure cost planning process includes design, manufacturing, injection molding, assembly, and logistics.

The entire process is carefully designed to give our customers the best possible ROI. We optimize your investment according to what is essential and what is not.

Don’t hesitate, please contact us to get an instant injection molding quote.

English

English 中文简体

中文简体 русский

русский